Description

Basket 850×725 mm

Useful height 645 mm

Baskets / h 20

Completely pressed tank stairs

Double wall

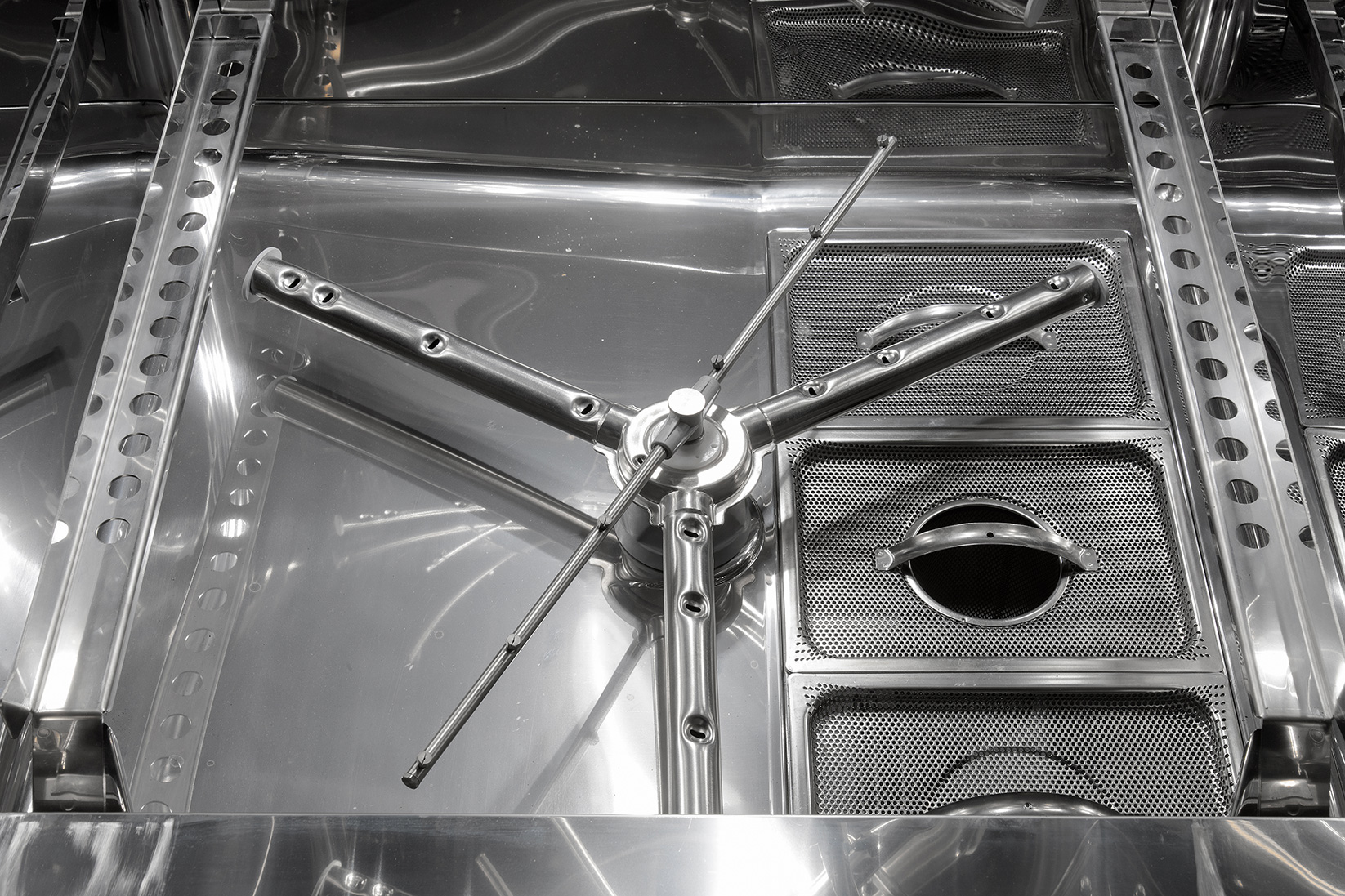

Wash / rinse arms in stainless steel self

Double tank filter with small removable sink for waste + pump filter

Self cleaning vertical pump

Series of rinse pump

Electronics

4 Cycle

Saving Energy

Thermostop to ensure rinsing temperature in accordance with HACCP

START touch pad with multi color

TR: STEAM CONDENSER AND HEAT HEAT ENERGY SAVINGS, ATTENTION TO THE ENVIRONMENT

AND WELL-BEING With models LP2 / 3/4 STR Over washing battery range and washing utensils, DIHR allows you to save the ! energy consumption up to 50% TR system is a collector / condenser mists: wet and hot steam is sucked directly when the door is still closed and used to heat the cold supply water to 50 ° C. This system reduces the energy consumption is required to wait 85 ° C for the final rinse is the annual cost for electricity. Depending on the model you can save: 3.5 kWh (lp2 / 3) to 5.5 kWh (Lp4) which correspond to € 2.810 * (LP2 / 3) and € 4.416 * (LP / 4) per year. * Calculated: 0.275 cent / kWh for 8 hours / day for 365 days / TR an.De more obvious how technology improves the quality of the premises. Through the heat exchanger, the air temperature discharged by the machine is reduced by more than half. Absolute humidity is a reduced about 20% compared to the vapors emitted by a machine without heat recovery, it ensures well-being of the operator key

SYTEME DIHR PLUS rinse water temperature and constant pressure. DIHR has developed a new flushing system temperature and pressure observations. With the system the more water is sucked from the superheater by a suppressor and sent to rinse nozzles ,: also With Break Tank machine is independent from the line pressure and the rinsing is ensured even in case of low water pressure . The water temperature remains constant during the entire rinse cycle (85 ° C), for recharging the boiler is made to finished rinsing, avoiding the mixing of the waters. System « Break Tank » prevents the return to the water supply of the machine network become undrinkable by the wash, rinsing and washing of the residue. This is a classified system AA « maximum effective » as required by the EN1 717 standard for « protection against backflow in the water network. »