Description

H useful 450 mm

Basket 500×500 mm

Normal speed 190 racks/h

Speed DIN 10510 135 racks/h

Maximum speed 300 racks/h

6840-3420/Mr

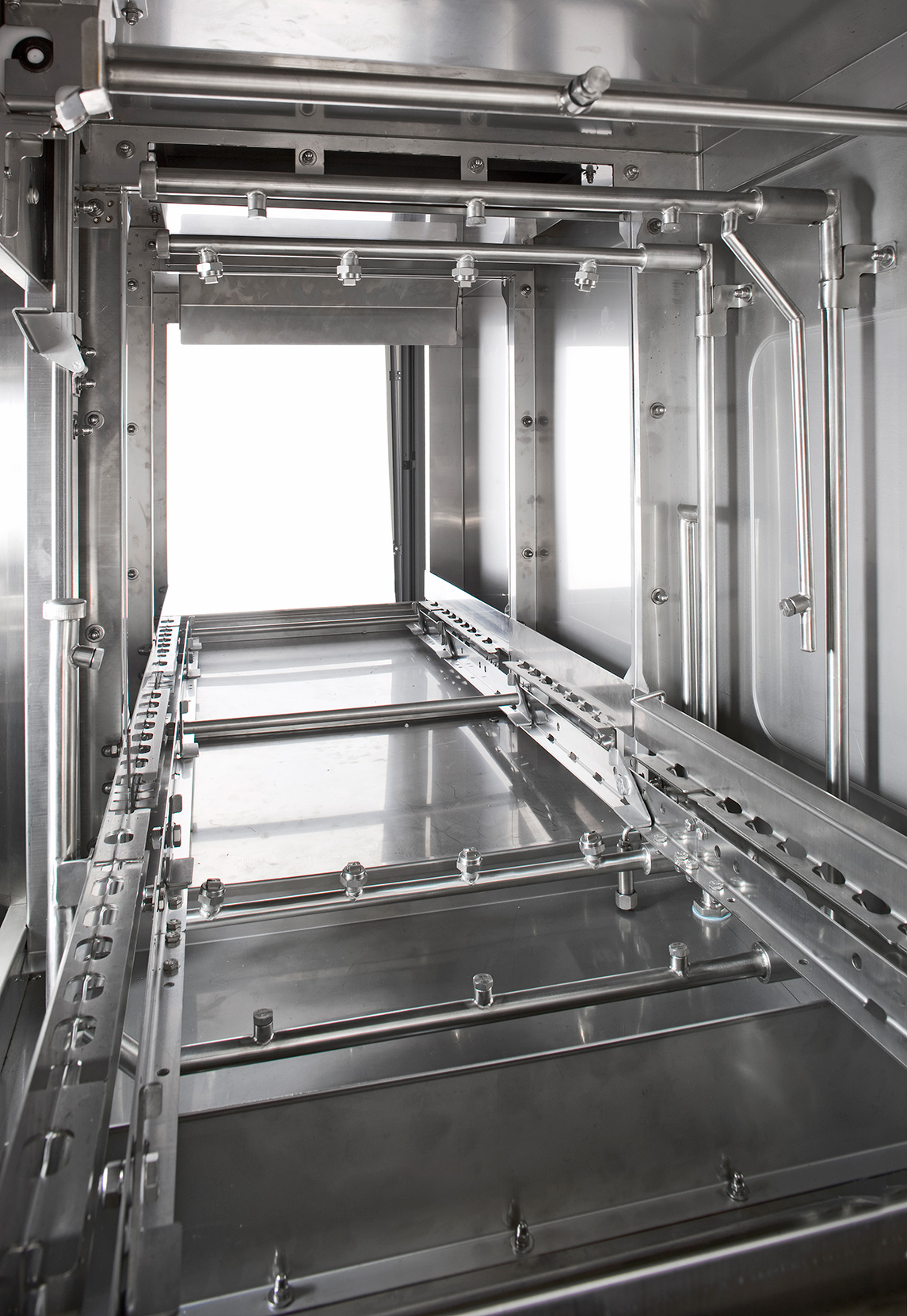

The dishwasher rack conveyor range RX OPTIMA reach new heights of efficiency.

The rinse system in three phases 3Rplus ensures water consumption considerably reduced and quality of the result. The rinse system in three phases 3Rplus ensures water consumption considerably reduced and quality of the result. The perfect thermal insulation of walls, reuse of the heat of the vapors produced inside the machine, the recovery of the heat of the water to the discharge, are some of the strengths of this range that features the cast down-chin total waste. The simplicity and ease of use characterize both the phase of work that the daily operations of cleaning and maintenance. The practical and large display simplifies access to the functions of the machine by the operator. The control panel IP55, the washing arms rack, the optional sanitizing machine and unloading system makes easier the operations end of the day.

STANDARD:

Voltage 400V3N50Hz.

Variable speed conveyor

Washing arms rack

Thermal and acoustic insulation

Isolation washing tanks

Rinse at variable flow

Centralized drain

Electrical panel IP55

Capacitive touch keypad and TFT display

Break Tank

Autotimer

Saving detergent (DDSS).

Self-cleaning battery heat recovery.

Electrical preparations dosing unit.

Interface Ready HACCP

Counter of operating hours.

Counter of water consumption,based on operating hours.

Counter power consumption,based on operating hours.

Ability to turn off the heating elements drying,during operation

OPTIONAL

HDR 200: Drying + Heat recovery.

HDRA209M ed HDRA218M:Drying + RecuperatoreTermico curve motorizzataa 90 ° or 180 °.

AS45:prewash module with filter drawer.

Emptying automated servo valves.

Sanitizing machine.

CentralinaTwindose.

Dispensers peristaltic.

Stainless steel washing pumps.

Supervisor HACCP.

Corner entry 90 ° with prewash.

Voltage 230-240V350Hz.

Extra Voltage 60Hz

Shipping more parts

BENEFITS FROM NEW HDR THERMAL RECOVERY + DRYING

Reduction of installed boiler

Reduction of installed drying

No additional consumption for maintaining the temperature of the prewash

Cooling air outlet and steam condenser.

Reduction of temperature of the waste water.

Pre-soak dishes.

HDR

The module HDR Heat recovery + Drying, achieves significant energy savings. Uses the heat, otherwise dispersed into the surrounding environment, to preheat both the rinsing water to which the air used for the asciugatura.Le working environment conditions are preserved due to the clearing of the outlet air temperature and discharge water and the total power installed is significantly reduced. The installation of this option allows the power of the machine with cold water and allows for the in-sciugatura dishes with zero operating costs compared to the same machine without optional HDR. The HDR module is available both online and on motorized curve at 90 ° or 180 ° (respectively HDR200, HDRA209M,HDRA218M).

AUTOMATED DRAINING

LESS WORK AND ALWAYS CLEAN WATER

Altermine work cycle just touch a button to empty the tanks, without needing to remove any overflow and enter into contact with the solution of lavaggio.Grazie to servo valves dedicated to each tank is possible to make the emptying of tanks sun prewash. This will ensure the continuous regeneration and balanced water prewash, without waste and with immediate benefit for the washing steps subsequent. With automated unloading, in addition to, the possibility of programming the filling and the heating of the tanks in anticipation of the work session later, allows to reach the maximum level of comfort.

CONSUMPTION

3R PLUS

The gaming rinsing 3Rplus is characterized by three phases, two of which utilize circulating water and remove most of the detergent from the crockery. Thanks to the nozzles and the differentiated system break-tank with electric pump dedicated, the flow of water on the dishes is always well distributed and constant. The inverter series, a pump control rinse, for-puts to calibrate the water consumption to the actual speed of advance of the convogliatore.Inoltre, the consumption of clean water at low temperature, for cooling the prewash, is completely demolished, grazie all’optional HDR.

USER INTERFACE

SIMPLICITY 'AND COMPLETENESS

The user interface with menus tiered and differentiated access, provides comprehensive and targeted both for the user and for the technician.

Large TFT 7 "

Capacitive touch control panel

Hotkeys peri commands operator

Continuous monitoring of the working parameters

Detailed information on alerts

Information relating to the hours of operation and fuel consumption.

Historical alarms and events

Interface HACCP

Level management of chemicals and related alarms and information

Reminder scheduled maintenance

Tips to maximize performance and efficiency